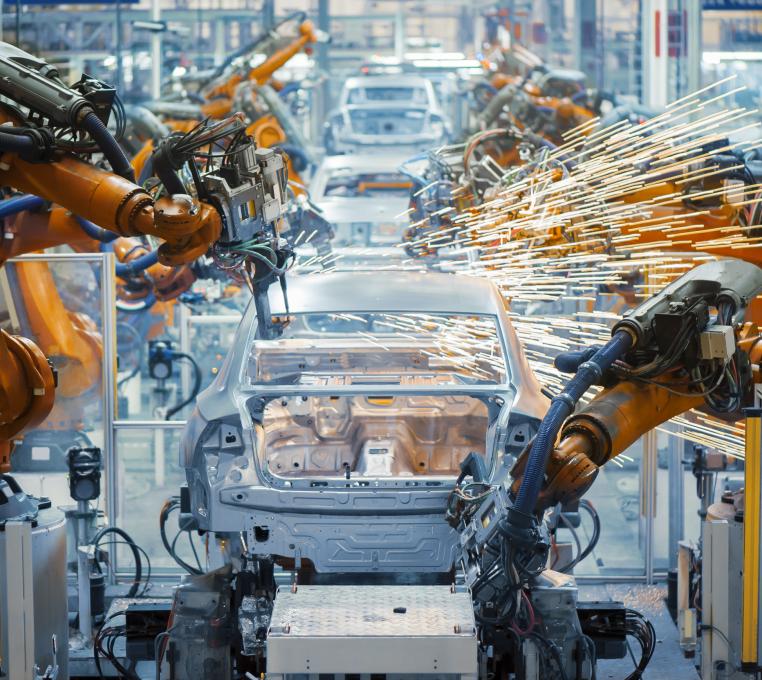

We offer comprehensive services in the area of robots and automation. We develop and the commission robot cells and lines. We provide comprehensive assembly, programming, implementation and service.

ROBOTISATION

The project begins with a computer simulation that will guarantee the confirmation of preliminary assumptions. In this way, the project execution time is reduced.

We develop robot applications for:

- Palletisation

- Gluing

- Transport

- Machine services

- Heat joining, welding, laser cutting

We also provide the entire control, visualisation and supervision system. Upgrades and expansions of existing automation systems as well as PLC programming are also on offer.

Procedure course:

1. We begin with station design.

2. We execute commissioning at our facility.

3. We confirm the process operation and cycle time by way of tests.

4. Upon acceptance, we provide comprehensive assembly at the customer site.

5. We provide operator training and production assistance.

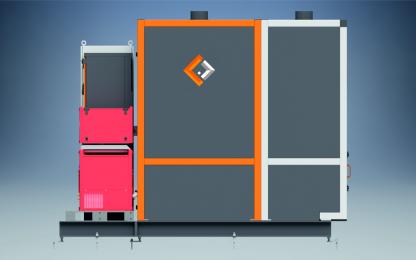

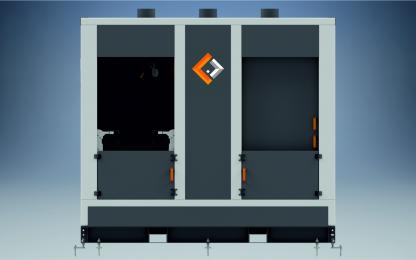

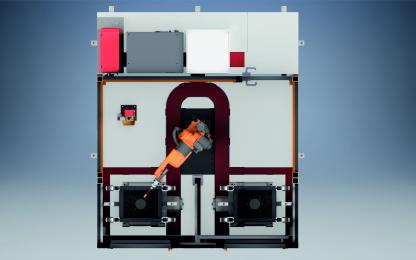

We develop robotic turnkey welding systems. We make solutions tailored to the customer's needs, who selects individual components of the cell in accordance with its requirements and budget. We are flexible - we build solutions based on many leading manufacturers of industrial robots and welding sources, in MIG-MAG, TIG, CMT welding technologies. In our implementation laboratory, we first test the possibility of using a given technology for the customer's needs followed by implementation phase.

Robotic systems and industrial robots

In addition to welding systems, we supply plug-and-play systems for mobile robotic solutions for applications such as gluing, palletising, pick & place. We have in our offer exclusive Soft Robotics technology in Poland, which allows to move brittle, food and soft elements, which until now could not be easily moved using traditional technology. Our systems can be moved by means of a forklift truck, connecting only to the media, which gives an unbelievable possibility to use them in various places in production plants. We also build tooling systems that allow the workpiece to be rotated during the process, e.g. welding, so that the industrial robot is able to quickly and precisely reach any place even inaccessible.